High-rise buildings have become indispensable symbols of modern cities. These are structures of exceptional height, defined by the standards of each country, playing a pivotal role in solving the challenges of living and working space by maximizing the use of valuable land. The development of skyscrapers not only reflects economic strength but also serves as a testament to the remarkable progress in construction science and engineering.

To meet the ever-increasing demands for speed, quality, and sustainability, advanced construction solutions like steel structures are becoming the top choice. Selecting a reputable general contractor with sufficient capacity and experience is the decisive factor for a project’s success. In both the Vietnamese and international markets, DaiDung Group has affirmed its pioneering position as a trusted partner for large-scale, technically complex high-rise projects with the strictest quality standards.

The Construction Sequence of a High-Rise Building

A successful high-rise project requires a construction process that is meticulously planned and controlled through every stage. Below is the standard construction sequence applied to major projects.

1. Preparation Phase

- Project Planning, Design, and Legal Procedures: Complete design drawings, cost estimates, and the overall schedule; obtain construction permits, secure land use rights, and ensure environmental protection; have the project appraised and approved before implementation.

- Site, Manpower, and Material Preparation: Level and clear the site, install security fencing and create transport access points; prepare materials, machinery, and equipment; recruit and train workers, providing them with full personal protective equipment. Conduct a comprehensive safety inspection of all machinery, equipment, emergency exits, and warning signs.

2. Foundation Works

- Geological Survey, Foundation Design, and Reinforcement: Use machinery to drive reinforced concrete piles, ensuring the foundation’s load-bearing capacity meets the standards for the specific soil type and project scale. Steps include preparing materials and equipment, conducting load tests, mass pile driving, and quality acceptance of the foundation piles.

- Reinforced Concrete Foundation Construction: Excavate foundation pits; pour blinding concrete; install steel reinforcement and formwork; pour concrete for the foundation and tie beams; build foundation walls and underground tanks; finally, conduct a rigorous inspection and acceptance of the foundation, as it determines the stability of the entire structure.

3. Superstructure Construction (Frame, Floors, Walls, etc.)

- Construction of Columns, Beams, and Floors (repeated for each level): Install steel reinforcement and formwork, pour concrete, and build walls and stairs for each floor. Conduct an inspection and acceptance before moving to the next level.

- For super high-rise buildings, high-quality materials and advanced equipment are essential (high-performance concrete; standardized, self-climbing, or hydraulic slip formwork systems; core-climbing cranes; on-site concrete batching plants) to meet the demands for construction speed, safety, and quality control.

4. Roofing Construction

- Insulation and Waterproofing: Install an insulation layer and pour waterproofing concrete. Create a slope for water drainage, finish the roof surface (tiling, drainage system), and conduct a water test and acceptance before proceeding.

5. Finishing Phase

Execution of various tasks, including:

- Plastering walls, finishing ceilings, tiling walls and floors, installing doors, and fitting MEP (Mechanical, Electrical, Plumbing) systems, including air conditioning and fire protection.

- Applying waterproof coatings, painting, and conducting partial inspections and acceptance.

- Adhering to the principle of working from top to bottom and from inside to out to ensure cleanliness and final quality.

6. Project Handover and General Cleaning

- After all construction and finishing stages are complete, the building will undergo a final industrial cleaning, a comprehensive final inspection, and will then be handed over to the project owner for use.

Advantages and Applications of Steel Structures in High-Rise Buildings

Steel structures are increasingly used in modern high-rise construction due to their outstanding technical and economic advantages, aligning with global trends in advanced technology and meeting the technical and quality control standards in Vietnam.

- Shorter Construction Time: Steel components are precisely fabricated in the factory, then quickly transported and assembled on-site, which accelerates the overall project timeline and reduces weather-related delays compared to traditional concrete construction.

- Overall Cost Savings: A shorter schedule reduces not only direct costs but also indirect costs (management, security, capital costs). It also maximizes usable floor space due to smaller column cross-sections and reduces foundation loads compared to heavier materials.

- Strict and Consistent Quality Control: Steel structure manufacturing adheres to international quality inspection standards. On-site work primarily involves assembly and connection checks, minimizing defects.

- Easy Expansion or Dismantling for Reuse: Steel structures are very convenient for renovations, spatial expansions, and relocation when necessary.

- Easy Maintenance and Repair: Inspecting, maintaining, and replacing steel components is straightforward due to the clear, assembled structure of the connections.

- Effective Load Control: The structural weight is significantly lower than that of reinforced concrete, reducing the load on the foundation and its associated costs. This is particularly suitable for sites with weak soil or for projects requiring great heights.

DaiDung Group – A Leader in the High-Rise Steel Structure Industry

DaiDung Group is a leading steel structure contractor in Vietnam. Established in 1995, DDC Group has built a superior brand reputation not only domestically but also in the international market. With the mission to “Bring Vietnam to the world” and an ambition to become a leading global steel structure solutions group.

DaiDung Group’s steel structure products are present in over 60 countries and territories, making significant contributions to the civil, industrial, renewable energy, and architectural construction sectors. Beyond being a general contractor, DaiDung Group also excels in designing oversized and super-heavy components for international-scale projects.

DaiDung Group’s Main Product Lines

DaiDung Group offers a diverse range of high-strength products and services:

- Steel structures for high-rise buildings

- Steel structures for industrial plants

- Steel structures for renewable energy and power transmission

- Steel structures for architectural works, bridges, ports, workshops, technical modules, fish farm stations, and hydrogen modules

- Pipes, tanks, heavy industrial oil tanks, telecommunication steel structures, and hot dip galvanized steel.

Landmark High-Rise Projects by DaiDung Group in Vietnam and Internationally

The capability and reputation of DaiDung Group are affirmed not only through key domestic projects but also on a global scale, successfully conquering markets with the world’s highest technical and safety standards, such as Japan. Below are some landmark projects that demonstrate our leading position in the field of steel structures for high-rise buildings.

Koji High-Rise Building – Japan

The Koji building project is a clear testament to the confidence that major Japanese general contractors and project owners have in DaiDung’s manufacturing capabilities. For this project, we undertook the fabrication and supply of complex steel structure components that required near-absolute precision. All products fully complied with the Japanese Industrial Standards (JIS) system for technical tolerances, material quality, and durability.

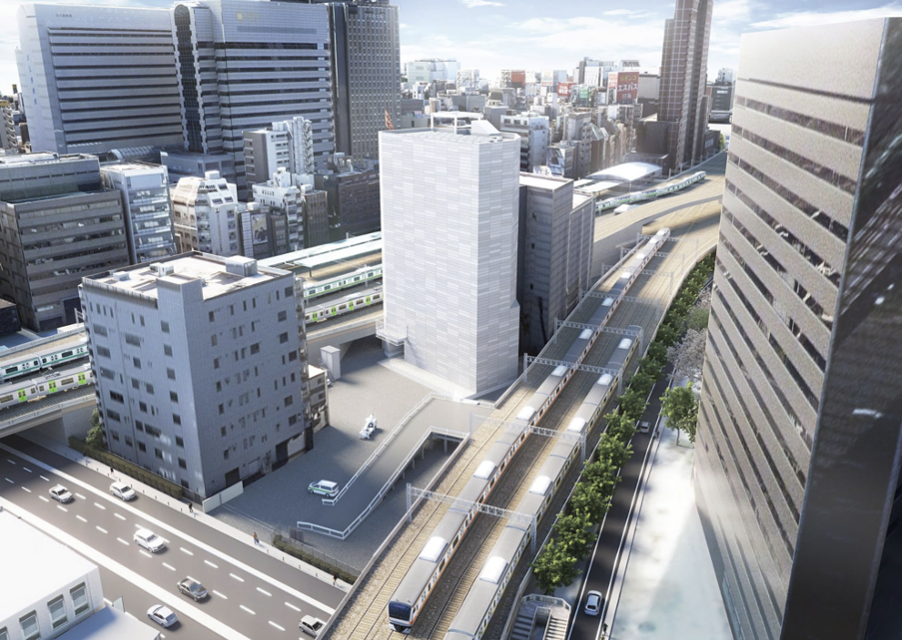

Shinhenden Power Plant – Shinjuku

Participating in the Shinhenden power plant project in Shinjuku is a great source of pride, as DaiDung Group contributed to the vital energy infrastructure of one of the world’s busiest metropolises. We supplied the load-bearing steel structure system for the plant, which generates power for the entire railway system of the capital, Tokyo. The project demanded the highest level of precision in every fabrication detail and the ability to withstand harsh operating conditions.

Nihonbashi High-Rise Building

The Nihonbashi building is not just an ordinary high-rise but a green architectural icon and a sustainable masterpiece of modern Tokyo. DaiDung Group was the contractor that supplied the steel structure, forming the strong “skeleton” for this iconic project. The steel components we produced not only ensured superior load-bearing capacity, meeting Japan’s highest anti-seismic standards, but also had to align with the strict aesthetic and functional requirements of a green building.

Suntory High-Rise Building

The Suntory high-rise is one of Tokyo’s prominent buildings, where the Suntory corporation houses its modern offices and facilities, combining green architecture and advanced technology with high-quality steel structures. DaiDung Group excellently fulfilled its role, providing top-tier steel structures that helped create a world-class, sustainable, and inspiring workspace, befitting a global brand.

In conclusion, a high-rise building construction process that adheres to international standards is the backbone that determines the safety, quality, and longevity of any building. Therefore, selecting an optimal construction method and a partner of sufficient stature is a strategic decision.

Partnering with a professional and internationally experienced general contractor like DaiDung Group is not just a choice, but a smart investment for the project’s future. We provide comprehensive peace of mind, from solution consulting and component manufacturing to erection and project handover.

DAI DUNG MECHANICAL CONSTRUCTION TRADING JOINT STOCK COMPANY

- Address: Lot 38, Area C, D1 Street, An Ha Industrial Park, Tan Vinh Loc Commune, Ho Chi Minh City, Vietnam

- Office: 121 – 123 Bach Dang, Tan Son Hoa Ward, Ho Chi Minh City.

- Phone: +84 28 3868 1689