In critical industries such as chemicals, petroleum, food, and even for building fire protection systems, safe and standardized storage is a top priority. Any error in storage can lead to severe safety risks and economic losses.

Steel tank design is the professional solution to this challenge. It is the comprehensive process of calculating, selecting materials, and fabricating a containment system (for water, chemicals, petroleum, etc.) that guarantees durability, leak prevention, and adherence to the most stringent technical standards.

Common Applications of Steel Tanks

Steel tank design is highly versatile, meeting diverse needs in both industrial and civil sectors:

- Fire Protection Water Tanks: Ensuring water reserves for firefighting, compliant with standards like TCVN and NFPA.

- Chemical Storage Tanks: Resistant to corrosion, safely storing various acids, bases, and solvents.

- Petroleum and Fuel Tanks: Specialized designs for gas stations and fuel depots.

- Wastewater Treatment Tanks: Containing and processing industrial and domestic wastewater.

- Industrial Process Tanks: Used in the food, pharmaceutical, and manufacturing sectors.

Why Choose Steel Tanks Over Other Materials?

Steel tanks offer numerous outstanding advantages, often affirmed and proven in domestic regulations and mandatory international standards for industrial storage.

High Durability and Strength

Steel tanks are typically made from carbon steel, stainless steel, or alloy steel, capable of withstanding significant pressure and mechanical impacts. Fabrication methods, along with protective coatings like galvanizing, epoxy, or polyurethane, extend their service life to 20-50 years, even in Vietnam’s harsh environmental conditions.

Furthermore, all steel tank products must undergo rigorous inspection: ultrasonic testing (UT) and radiography (RT) of welds, and hydrostatic pressure testing before use, complying with national standard TCVN 8366:2010 and Vietnamese laws on pressure vessel management.

Corrosion Resistance and Safety

Stainless steel or specialized steels offer resistance to chemicals, seawater, and oxidation, enduring harsh weather and ensuring long-term sustainability. To enhance protection, tanks use hot-dip galvanizing or specialized coatings compliant with ASTM standards, improving lifespan and efficiency.

Reputable manufacturers also apply cathodic protection technology, reducing the risk of electrochemical corrosion in marine environments, and adhering to strict chemical and environmental safety requirements under Vietnamese law and international standards like ASME and API.

Versatility in Design and Application

Steel tanks can be designed in various capacities, from a few cubic meters to thousands, suitable for needs ranging from residential areas to large petrochemical refineries or industrial parks. Flexible manufacturing allows for vertical tanks, horizontal tanks, high-pressure vessels, or specialized chemical containers. Consequently, steel tanks are widely used for storing fresh water, chemicals, petroleum, LPG, and in wastewater treatment and food processing.

Compliance with High Standards and Ease of Maintenance

Most industrial steel tanks today must comply with international standards such as ASME (USA), EN (Europe), JIS (Japan), and national TCVN standards, ensuring safety, quality, and sustainable operation.

Strict inspection processes for materials, dimensions, welds, and pressure testing are mandated by pressure equipment management laws (such as Decree No. 13/2020/ND-CP and TCVN 8366:2010), contributing to operational and environmental safety. Modern tank designs also facilitate convenient maintenance, inspection, and component replacement.

Standard Steel Tank Design Process per National (Vietnam) Standards

TCVN 10262:2014: Specifies requirements for the design, fabrication, inspection, and testing of steel tanks for flammable and combustible liquids. Provisions include:

- Material: Must be commercial-quality low-carbon steel or stainless steel.

- Thickness: Calculation of tank shell thickness must be based on liquid pressure, working loads, and a corrosion allowance.

- Accessories: Requires proper arrangement of accessories such as vents, manholes, and liquid level indicators; and control of fill levels not to exceed limits.

- Pressure: Vapor space pressure must not exceed 35 kPa; the length-to-diameter ratio of above-ground tanks must not exceed 5.

- Stiffening: Stiffening of the tank shell is not permitted except in special designs; thinner materials may be allowed if shaped, corrugated, or stiffened to ensure equivalent mechanical properties.

TCVN 8615:2010 (Part 1): Covers the design and site fabrication of vertical, cylindrical, flat-bottomed steel tanks for refrigerated liquefied gases or liquids. The process includes:

- Selecting appropriate tank shape and dimensions for the intended volume and location.

- Fabrication and installation adhering to technical safety inspections, foundation settlement prevention, and leak/weld crack prevention.

Standard Steel Tank Design Process per International Standards

International codes for steel tank design, issued by organizations like API (USA) and Eurocode (Europe), establish strict principles for materials, construction, inspection, and safety.

API 650 – International Standard for Large Steel Tanks

API 650 is the world’s most common standard for the design, fabrication, and installation of large steel storage tanks, especially in the petrochemical, water, food, and general industrial sectors.

- Specifies the use of quality-inspected carbon steels (e.g., ASTM A36, A283, A573) or stainless steels.

- Calculates the thickness of shell and bottom plates based on liquid pressure, wind, seismic loads, roof loads, operational loads, and corrosion allowance.

- Provides detailed guidance on tank foundations, soil bearing capacity checks, concrete ring walls, storm anchorage, and methods to control tank settlement.

- Mandates quality checks for welds, such as ultrasonic testing (UT), radiography (X-Ray), water tightness tests, and pressure tests.

EN 14015 – European Standard for Steel Tanks

EN 14015 is the European standard for the design, fabrication, installation, and testing of vertical, cylindrical, flat-bottomed, welded steel tanks.

- Requires material verification (selecting correct alloy groups, verifying origin).

- Mandates comprehensive calculation of all loads: internal liquid pressure, environmental loads (wind, snow, seismic), operational loads, and thermal impacts.

- Specifies implementation of non-destructive testing (NDT) and water tightness tests.

- Details requirements for corrosion protection, including external coatings, hot-dip galvanizing, and epoxy paint.

Eurocode 3 (EN 1993-4-2) – Structural Design and Stability of Steel Tanks

Eurocode 3 (EN 1993-4-2) focuses on the structural design and stability of steel tanks.

- Scope: Applies to vertical cylindrical, rectangular, and flat-bottomed steel tanks with large storage capacities.

- Resistance: Ensures resistance to hydrostatic loads and climatic extremes (design temperatures from -50°C to +300°C).

- Integration: Complements EN 14015 (ambient temperature tanks) and EN 14620 (cryogenic tanks).

DaiDung Group – Vietnam’s Leading Steel Tank Manufacturing Capability

With over 30 years of development, DaiDung Group (DDC Group) has not only secured its leading position in Vietnam’s mechanical engineering and steel structure industry but also possesses outstanding specialized capabilities in manufacturing pipes, tanks, and complex pressure vessels.

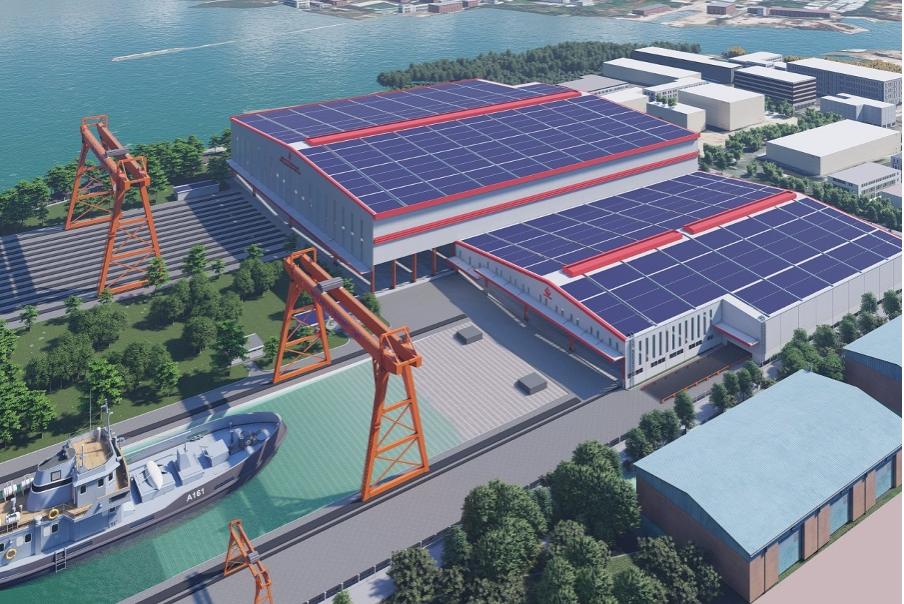

Specialized High-Tech Factory System

DaiDung Group operates high-tech factories specifically designed to handle complex mechanical products, including tanks and oil/gas pipelines. Two key facilities stand out:

1. Nghi Son High-Tech Mechanical Plant (Thanh Hoa): Specializes in products for LNG, thermal power, liquefied gas, heavy industry, and offshore projects. Its main products include pipes, tanks, and oil/gas pipelines. Phase I capacity reaches 73,000 MT/year.

2. Vung Tau High-Tech Mechanical Plant: Focuses on offshore, oil & gas, and seaport projects. The plant is equipped with super-large gantry cranes (500T and 1,000T) with a height of 120 meters.

International Quality Assurance (ASME & ISO)

DDC Group capability in pressure vessel manufacturing is globally recognized through the strictest international certifications from the USA (ASME), demonstrating compliance with the highest quality standards:

- U_ASME: Certification for the manufacture of pressure vessels.

- S_ASME: Certification for the manufacture and assembly of power boilers.

- R_NBBI: Certification for the repair and alteration of mechanical equipment.

- Other Certifications: Holds H GRADE certification and ISO 3834 (Comprehensive quality requirements for welding).

Superior Manufacturing Foundation

The foundation for DaiDung Group large-scale steel tank production capability is its system of 6 main factories, covering a total area of 120 hectares. The Group’s current total production capacity is 500,000 tons/year, with a growth target of 860,000 tons/year by 2030.

Proven Experience in Global Megaprojects

DaiDung Group capabilities have been proven through supplying tanks and piping for a series of key international and domestic energy and heavy industry projects:

- International Projects: East African Crude Oil Pipeline (EACOP) in Tanzania, Qatar LNG North Field Expansion EPC-2 (Qatar), and LNG projects in the USA (Plaquemines LNG, Three River Energy Center, Calcasieu Pass CP2).

- Domestic Projects: Nghi Son Refinery and Petrochemical, Long Son Petrochemical (Vung Tau), and Nhon Trach 3 & 4 LNG Thermal Power Plants.

Conclusion

Steel tanks are not just storage tools; they are a strategic solution in modern industry. With their high durability, safety, and flexibility, steel tanks play an increasingly central role in Vietnam’s energy, chemical, and infrastructure sectors.

DaiDung Group, with over three decades of experience, a modern factory system, and top-tier international certifications, has affirmed its position as Vietnam’s leading steel tank manufacturer, ready to reach the global market.

For a specific consultation on the optimal design and fabrication of steel tanks for your business, please contact:

DAIDUNG CONSTRUCTION TRADING MECHANICAL JOINT STOCK COMPANY

- Address: Lot 38, Area C, D1 Street, An Ha Industrial Park, Tan Vinh Loc Commune, Ho Chi Minh City, Vietnam

- Office: 121 – 123 Bach Dang, Tan Son Hoa Ward, Ho Chi Minh City.

- Phone: +84 28 3868 1689

- Fax: +84 28 3845 2397