With the capacity to execute large-scale, complex steel structure projects to international standards, DaiDung Group (DDC Group) has established itself as one of the leading steel structure contractors in Vietnam. Nearly 30 years of extensive experience and an impressive capability profile are a clear testament to the reputation and strength of DDC Group. This article will provide an in-depth analysis of the core competencies and review the iconic projects that have contributed to building DDC Group’s name in the market.

Introduction to DaiDung Group (DDC Group) – Vietnam’s Leading Steel Structure Contractor with Global Aspirations

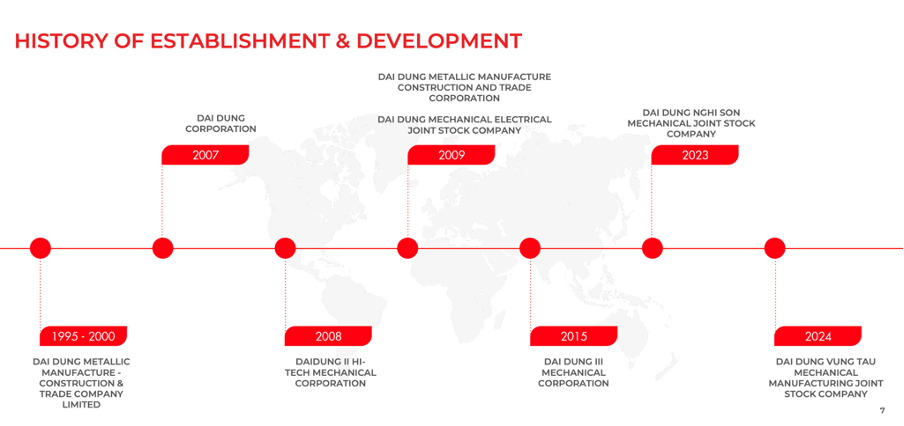

Established in 1995, DaiDung Group has undergone nearly three decades of continuous construction and development, rising to become a leading multi-industry corporation in Vietnam, with a particularly strong mark in the fields of mechanical fabrication, construction, and its core business of steel structures. Not limited to the domestic market, DDC holds a grand vision: “To become a world-class multi-industry corporation, a national brand, and a leading symbol of Vietnam.”

The mission of “PROUDLY BRINGING VIETNAM TO THE WORLD” is not just a slogan but is realized by DDC Group through each high-quality product and project, carrying the spirit of passion, aspiration, and creativity of the Vietnamese people to conquer the most demanding markets. Operating based on 5 core values: “ASPIRATION – PROFESSIONALISM – QUALITY – CREATIVITY – SUSTAINABILITY,” DDC always strives to be the leading reliable strategic partner in the design, fabrication, and erection of steel structures within the value chain of top global contractors, companies, and projects.

A message from Chairman Trinh Tien Dung emphasizes the business philosophy: “All actions are always aimed at sustainable development.” This is the guiding principle for all activities, from building an elite workforce and perfecting a professional governance system to promoting digital transformation, prioritizing the use of environmentally friendly materials, and reducing emissions in production. With a strategy focused on 5 “Excellence” factors by 2030 (Development, Customer Service, Governance, Team, Sustainable Development), DDC Group aims to become one of Asia’s top excellent enterprises and continue its position as a market-leading steel structure contractor.

Superior Manufacturing Capabilities of DDC Group: Scale, Technology, and International Standards

To realize its vision and mission, manufacturing capability is the solid foundation of DDC Group. The corporation has invested heavily in its factory system, technology, and management processes, creating a distinct competitive advantage in the market.

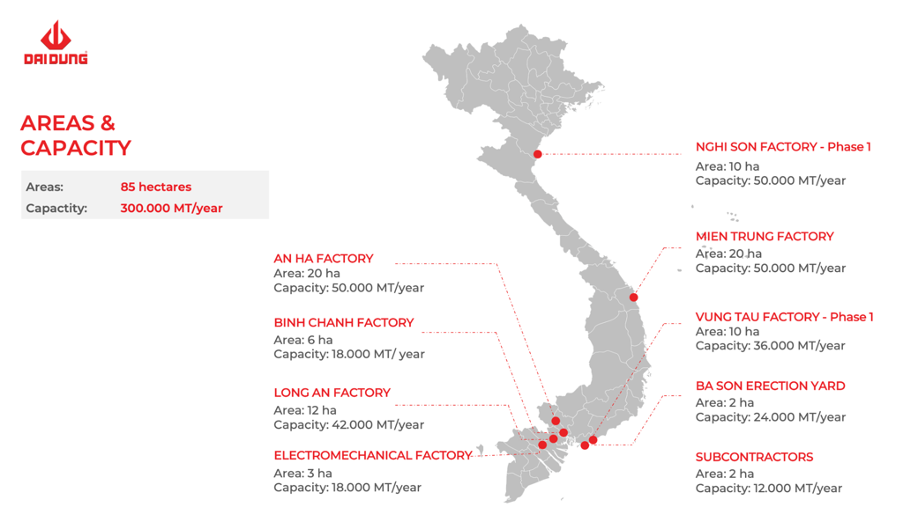

Impressive Factory Scale and Capacity: Currently, DDC Group owns 06 strategic manufacturing clusters located in logistically favorable locations (An Ha, Long An, Binh Chanh, Central Region, Ba Son, Nghi Son, Vung Tau) with a total area of up to 120 hectares. The current total design capacity reaches 500,000 tons of steel structures per year.

Furthermore, DDC Group has strong growth plans, aiming to increase the total area to 140 hectares and the capacity to 860,000 tons/year by 2030. Each factory is methodically invested in. For example, not only has a large scale but also meets stringent international certifications such as:

- ISO 9001:2015 (Quality Management)

- ISO 14001:2015 (Environmental Management)

- ISO 45001:2018 (Occupational Health and Safety)

- AISC Certification (American standard for structural steel fabrication)

- International welding certifications ISO 3834, EN 1090-1

- And notably, the LEED Gold green building certification – a testament to its commitment to sustainable development. Other factories like Nghi Son and Vung Tau are also planned to be built to LEED Gold standards.

Modern Technology and Equipment: DDC’s manufacturing strength also comes from its extremely modern and synchronized system of machinery and equipment. The corporation possesses a large number of advanced devices for key stages:

- Cutting and Forming: 71 units, including high-power CNC laser cutters, plasma cutters, press brakes, and plate rolling machines.

- Welding: 775 diverse welding units (Submerged Arc Welding – SAW, MIG/MAG, TIG…), ensuring weld quality meets international standards.

- Lifting: 271 units including overhead cranes, gantry cranes, and forklifts for moving large and heavy components.

Notably, DDC Group has also invested in specialized equipment for producing oversized and super-heavy offshore wind components, meeting the extremely complex technical requirements of the renewable energy sector.

International Standards and Advanced Software: Prioritizing product quality, DDC Group strictly applies popular international standard systems such as ASTM (USA), AS (Australia), EN (Europe), JIS (Japan), alongside TCVN (Vietnam) throughout the entire process from design, material procurement, and manufacturing to erection. The application of world-leading design, modeling (BIM), and project management software like Tekla Structures, SAP, and Primavera helps optimize design, control schedules, manage materials, and ensure high precision for every component. A coding system (barcode, QR code, RFID) is implemented for traceability, production data management, and efficient inventory control. Professional project management experience consistently makes DDC Group a reliable steel structure contractor.

Logistics and Export Capabilities: The strategic location of the factory clusters offers DDC Group to easily connect to major seaports (Cat Lai, Cai Mep, Nghi Son, Vung Tau…) and international airports, facilitating the transportation of oversized and super-heavy components worldwide. To date, “Made by DDC Group” steel structure products have reached over 60 countries and territories, serving key global projects.

DDC Group’s Extensive Experience through Landmark Steel Structure Projects Worldwide

Nearly 30 years of experience is the clearest proof of DDC Group’s capability and reputation as a steel structure contractor. The Group has participated in a series of large, complex, and iconic projects both domestically and internationally across various sectors:

- Industrial Plants: DDC Group is a trusted partner for many multinational corporations building factories in Vietnam and the region, such as HULIC (Japan), SUCHEL (Cuba), Coca Cola (Cambodia, Long An), PepsiCo (Can Tho), Bridgestone (Hai Phong), and Brother (Vietnam). These projects demand high standards of quality, schedule adherence, and safety.

- High-Rise Buildings: DDC Group supplies steel structures for modern high-rise buildings and complexes like KOJI, SHINHENDEN (Japan), NIHONBASHI – a symbol of green construction in Japan, and the unique glass skywalk at the Happy One Central project (Binh Duong).

- Renewable Energy: This is a field where DDC Group demonstrates outstanding capabilities with world-class offshore wind projects like Greater Changhua (Taiwan). DDC Group has successfully fabricated massive and highly complex wind turbine foundation components such as suction buckets and transition pieces, which require extremely high technology and precision.

- Shipbuilding & Port Modules: DDC Group participated in fabricating RTG shore cranes for Tan Cang Port, and notably, the Shiplift Platform project for BAE Systems (USA) – one of the world’s largest ship lift systems, affirming its capabilities in super-heavy and oversized mechanical fabrication.

- Heavy Industry: Mineral mining and processing plants, and thermal power plants are structures that require high-strength, durable steel structures in harsh environments. DDC Group has participated in major heavy industrial factory projects such as the Manyar Smelter Project (Indonesia), the Nickel Factory (Cao Bang), the Ukudu Power Plant (Guam), and most recently, supplied steel structures for the Nhon Trach 3 & 4 LNG Power Plant project.

- Piping & Oil and Gas Tanks: DDC Group supplies pipe components, storage tanks, and steel structures for large-scale oil and gas projects such as the East African Crude Oil Pipeline (EACOP), the Nghi Son and Long Son refining and petrochemical projects (Vietnam), and LNG projects in the USA and Qatar.

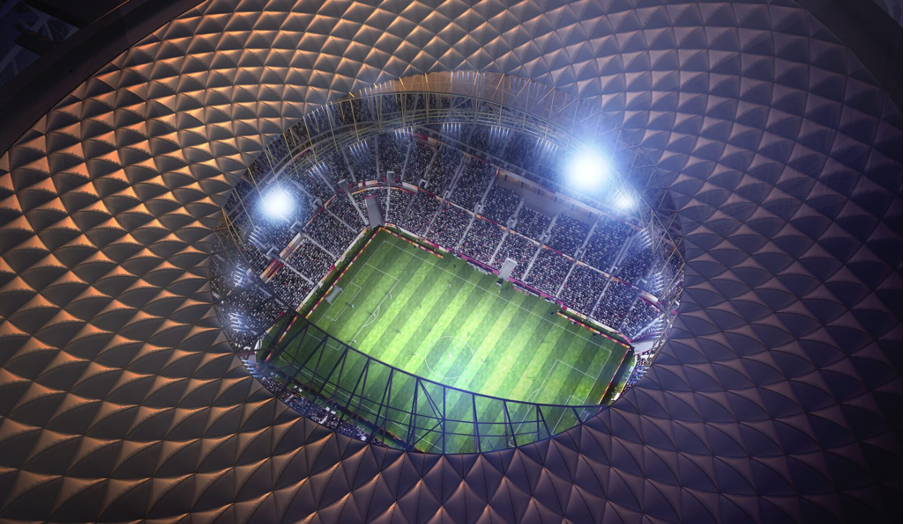

- Stadiums & Special Architectural Structures: This area best showcases DDC Group’s ability to design and fabricate complex, aesthetically pleasing steel structures. The Group is proud to be the only Vietnamese steel structure contractor to participate in 2 stadiums for the FIFA World Cup 2022 in Qatar: Lusail Iconic Stadium (where the final match was held) and Stadium 974 Ras Abu Aboud (a unique stadium designed with a modular steel structure and 974 shipping containers, which can be completely dismantled).

Other iconic projects include the Powerhouse Parramatta Museum (Australia – the greenest public building in Australia), the MISK ILMI Museum (Saudi Arabia), the Co Loa National Exhibition and Convention Center – one of the world’s top 10 largest exhibition centers – (Hanoi), and a series of key aviation infrastructure projects such as Terminal 3 of Tan Son Nhat Airport, Long Thanh International Airport, and New Phnom Penh Airport (Cambodia).

Commitment to Sustainable Development (ESG) – A Core Value of DDC Group

Beyond business operations, DDC Group places special emphasis on Environment, Social, and Governance (ESG) factors as the foundation for sustainable development.

- Green – Renewable – Circular Products: DDC Group prioritizes the use of recycled steel and high-strength steel to reduce material volume, while also providing reusable steel structure solutions to promote a circular economy.

- Clean Energy and Emission Reduction: DDC Group’s factories are pioneers in installing rooftop solar power systems, generating a significant portion of their electricity needs (An Ha 65%, Central Region 50%, Long An 60%). The construction of factories to LEED Gold standards (Nghi Son, Vung Tau) and the completion of a greenhouse gas (GHG) inventory according to ISO 14064-1 and ISO 14067 demonstrate a strong commitment to reducing its carbon footprint.

- Social Responsibility and Governance: The Group always cares for the material and spiritual well-being and development opportunities of its employees. DDC Group also actively participates in community activities, sponsoring children and disadvantaged people. In governance, DDC Group continuously improves its systems, prepares for an IPO, ensures financial transparency (audited by a Big 4 firm), and prioritizes access to green capital. Numerous prestigious awards such as the Excellent Labor Collective, the Prime Minister’s Certificate of Merit, and the Sao Vang Dat Viet award recognize these efforts.

Why Choose DDC Group as Your Steel Structure Contractor?

Based on the information above, DaiDung Group embodies all the elements of a leading steel structure contractor:

- Extensive Experience: Nearly 30 years of operation with hundreds of large and small projects domestically and internationally.

- Superior Manufacturing Capacity: A system of large-scale factories with high capacity and modern technology.

- International Quality: Strict adherence to international standards (ISO, AISC, EN, JIS…) and rigorous quality management processes.

- Comprehensive Solutions: Providing end-to-end services from design and fabrication to erection.

- Proven Capability for Complex Projects: Demonstrated through iconic, technically demanding structures.

- Commitment to Sustainability (ESG): A reliable partner for projects aiming for green standards.

- Established Reputation: Confirmed through the trust of major global clients and partners, and prestigious awards.

The capability profile of DaiDung Group (DDC Group) presents a clear picture of a Vietnamese steel structure contractor that is resourceful, professional, and has a global vision. With a solid foundation of experience, manufacturing capacity, modern technology, an elite workforce, and a strong commitment to quality and sustainable development. DDC Group is not only a top choice for steel structure projects in Vietnam but also a reliable and competitive partner in the global market. Choosing a DDC Group means choosing peace of mind in quality, schedule, and efficiency for every project.