In the global construction and steel structure industry, building world-class stadiums is always a challenge, demanding outstanding technical capabilities, complex project management experience, and strong financial resources. In Vietnam, DaiDung Group has made a significant mark through numerous large-scale sports projects, affirming the position of a Vietnamese brand on the international stage.

DaiDung Group: A Journey of Creating Icons

- History and Development: Starting in 1995 with a mechanical workshop, DaiDung Group has undergone an impressive development journey. Through strategic vision, systematic investment, and a spirit of continuous innovation, DaiDung Group has made a spectacular transformation from a local enterprise into a leading heavy industry corporation, a “giant” in the field of manufacturing and erecting steel structures.

- Business Sector: Dai Dung Group serves as a main EPC (Engineering, Procurement, and Construction) contractor, with expertise in manufacturing, supplying, and installing steel structures for major industrial constructions. The group’s extensive portfolio covers a wide range of projects, such as heavy industrial plants, multi-story factories, airports, seaports, bridges, complex high-rise buildings, and particularly, sports stadium construction.

- Mission: With great ambition, DaiDung Group has always pursued the mission of “Bringing the Vietnamese brand to the international level.” The group continuously pioneers the application of new technologies, creates optimal technical solutions, and is strongly committed to sustainable development, thereby contributing to the construction of projects that are not only economically valuable but also symbols of Vietnamese intellect and prowess.

Over 30 years, DaiDung Group has become a leading brand in the field of high-tech steel structures.

DaiDung Group’s Position and Capabilities in Stadium Construction

Being selected as a contractor for stadium projects, especially those serving global sporting events, is the clearest evidence of DaiDung Group’s capabilities and prestige.

- Factory System and Outstanding Production Capacity: Dai Dung Group owns a system of 6 modern steel structure manufacturing plants, spanning a total area of 120 hectares. The total production capacity reaches 500,000 tons/year, with a strategic goal of reaching 860,000 tons/year by 2030. The production lines are highly automated, applying the most advanced technologies from Europe (G7) and meeting the strictest international standards. This allows Dai Dung Group to produce oversized and overweight steel components with absolute complexity and precision—a core element in the dome roof structures of modern stadiums.

- Technology, Human Resources, and Professional Project Management: With a team of over 6,000 experienced employees, engineers, and experts, Dai Dung has mastered advanced design, simulation, and management technologies (BIM, Tekla, SAP). The group’s capabilities are also certified by over 100 prestigious domestic and international awards and certifications, ensuring that the project management process is carried out scientifically, strictly adhering to standards of progress, quality, and labor safety.

- International Cooperation Experience and Global Event Footprint: Affirming its position on the international stage, DaiDung Group’s steel structure products have been exported to over 60 countries. The group is a strategic partner of many leading global general contractors and construction corporations.

Mark on International-Standard Stadium Projects

Dai Dung Group has directly participated in supplying and erecting steel structures for stadiums serving major sporting events such as the World Cup. Meeting the complex technical requirements of these projects not only affirms Dai Dung Group’s capabilities but also enhances the position of Vietnam’s construction industry.

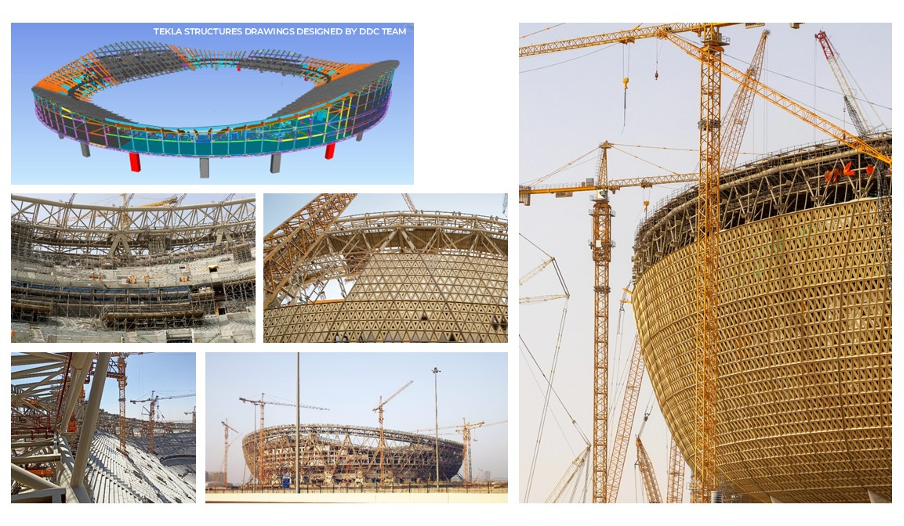

1. Lusail Iconic Stadium (Qatar)

The Lusail Iconic Stadium is inspired by the Arab “Fanar” lantern, symbolizing the interplay of light and shadow. The exterior is gold-plated with Islamic art motifs, and triangular openings allow light and shade inside. The roof, made of modern PTFE material, is dust-resistant, protects against moisture, and aids in cooling.

The stadium’s cooling system uses solar energy and incorporates a water-saving solution that is 40% more efficient than conventional stadiums, achieving a “zero carbon emissions” standard for the event.

This was the venue for the 2022 World Cup final and opening ceremony, with a capacity of over 80,000 seats, notable for its advanced cooling solutions and large-scale architecture. DaiDung Group manufactured and supplied nearly 6,000 tons of steel components, accounting for about one-fourth of the stadium’s total.

To achieve this, DaiDung Group underwent a rigorous appraisal process, including factory evaluations by the client and international organizations. The entire production was completed in just one year amidst the global disruptions caused by the COVID-19 pandemic.

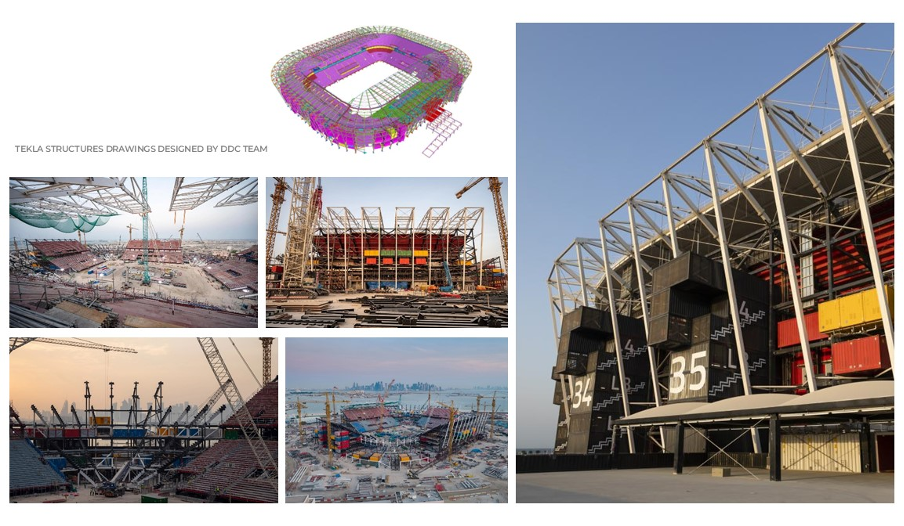

2. Stadium 974 (Ras Abu Aboud, Qatar)

Stadium 974, with a capacity of 40,000 seats, is the world’s first fully demountable modular stadium, constructed from 974 recycled shipping containers, aiming for sustainable development and reduced emissions. The design concept honors the country’s international trade and maritime industry.

DaiDung Group was responsible for supplying the entire 28,000 tons of steel structure, applying advanced modular construction solutions to ensure a precision of just 2mm for every detail.

This project created a mark for Vietnam in the global green supply chain and affirmed its outstanding capabilities in engineering, construction, and project management.

DaiDung Group’s Outstanding Values and Contributions Through Stadium Projects

Participating in international-caliber stadium projects is not just an economic contract but also an opportunity to affirm a nation’s capabilities and position on the world stage. As the steel structure contractor for these iconic projects, DaiDung Group has created immense value and contributions, becoming a source of pride for Vietnamese industry.

Putting Vietnam on the Global Supply Chain Map

DaiDung Group’s most profound mark was the construction of the steel dome for Lusail Stadium (Qatar)—the venue for the 2022 World Cup final. This was not just an ordinary project but a world-record steel structure marvel.

The fact that a Vietnamese enterprise was chosen and entrusted to be the only company from Vietnam in the supply chain for the world’s largest sporting event shattered preconceptions about the capabilities of domestic contractors. DaiDung Group proved that Vietnamese businesses can compete on an equal footing with the world’s leading corporations in a field that demands high technology and absolute precision. This success has placed Vietnam on the global supply chain map for mega-projects, establishing it as a reliable partner capable of providing the most complex technical solutions.

Affirming Prestige Through Media and International Recognition

DaiDung Group’s capabilities are not only demonstrated through its projects but also through widespread recognition. An article in Vietnamnet called DaiDung Group “the builder of the world-record steel dome“, a proud acknowledgment of the intellect and spirit of the Vietnamese people.

Mr. Trinh Tien Dung – Chairman and CEO of DaiDung Group speaks at the 30th-anniversary ceremony.

The trust of leading international general contractors like Hyundai E&C (South Korea) and CSCEC (China) in entrusting the most difficult and crucial part of the Lusail stadium is a golden guarantee of DaiDung Group’s quality and prestige. Furthermore, continuously achieving strict international certifications from bodies like the American Institute of Steel Construction (AISC) and the American Welding Society (AWS) shows that DaiDung Group consistently maintains a top-tier quality management system and production capacity.

Breakthrough Solutions for “Lightning-Fast” Progress

Facing unprecedented challenges such as the COVID-19 pandemic disrupting global supply chains and the extremely tight schedule of just 8 months for nearly 10,000 tons of complex steel structures, DaiDung Group implemented creative and decisive solutions:

- Smart Transportation Planning: The DaiDung Group team had to solve a complex “transportation puzzle,” finding optimal sea routes and innovating in logistics to deliver oversized and overweight components from Vietnam to Qatar safely and on schedule.

- Applying Precision Manufacturing Technology: For the 3D spatial structure composed of tens of thousands of different components, DaiDung Group applied the most modern technology to manufacture with near-absolute precision. This allowed for quick and perfectly matched assembly on-site, saving time and costs.

- Leveraging Human Potential: The project’s success is deeply marked by the Vietnamese spirit. The team of engineers and workers at DaiDung Group worked tirelessly, demonstrating intelligence, determination, and extraordinary adaptability to overcome all difficulties and bring the project to a timely completion.

These contributions not only bring value to DaiDung Group but also inspire and build confidence in the capabilities of Vietnamese enterprises on their path to conquering new heights.