Steel structure is one of the most fundamental and important solutions in the modern construction and industrial sectors. Although a relative newcomer compared to traditional materials like wood or concrete, steel rapidly dominated the market from the 20th century onward thanks to its ability to meet demands for streamlining, cost optimization, and outstanding durability.

This article will explore in-depth what a steel structure is, its history, its key applications in heavy industry, and the technical properties that have secured its prominent position.

What is a Steel Structure?

A clear distinction must be made:

- Steel: This is the material (an alloy of iron and carbon).

- Steel Structure: This term refers to the components or a complete building assembled from steel materials.

Simply put, a steel structure is a load-bearing system designed and fabricated primarily from steel components (such as beams, columns, trusses) that are interconnected to transfer and withstand loads. It is considered a cornerstone material of industry, used for everything from small details and architectural accents to massive load-bearing components.

1. Steel Structure Through the Ages

1.1 Steel as an Auxiliary Detail in 19th-Century Projects

The use of steel in factory construction during this period was still new. Typically, production workshops and factories were built using wood or concrete. However, the development of steel production technology and new fabrication methods opened up possibilities for using steel in factory structures.

1.2 Steel Structure Affirms its Position in 20th-Century Construction

In this era, the use of steel structures in factory construction became more common. Steel production and fabrication workshop technologies developed rapidly. This spurred the production of steel components in greater quantities and with more features. Factory buildings constructed with steel structures became prevalent, thanks to their flexibility and increased load-bearing capacity. Steel structure systems in this period were often based on steel frames, columns, and beams.

By the 20th century, steel structure became the choice for primary and secondary frame systems, and major load-bearing components in factories, pre-engineered buildings, and warehouses.

1.3 The Golden Age of Steel Structure (and No Signs of Slowing Down) in the 21st Century

In the modern era, marked by breakthrough and spectacular milestones, steel structures, especially in factory construction, continue to improve comprehensively with superior features. Component fabrication and processing technology are increasingly advanced. This has allowed workshops and corporations to create products with higher quality and lower production costs. The application of information technology and 3D modeling facilitates more accurate and efficient design and construction of steel structure factories. Furthermore, the trend towards sustainability and greener construction has promoted the use of recycled steel and fire-resistant steel structures.

Today, steel structures have become commonplace and are continually advancing in technical quality and forming capabilities.

In summary, from the 19th century to the present, the trend of steel structures for factories has undergone continuous development and improvement. Advanced steel production technology and the development of construction technology have played crucial roles in promoting the use and refinement of factory steel structures.

2. Steel Structure in the Industrial Sector

2.1 Common Applications:

A steel structure is a type of construction built primarily from steel materials, fabricated and processed for use in industrial projects:

Daidung is proud to have supplied structural steel components for the construction of Stadium 974 in Qatar for the 2022 World Cup.

- Pre-engineered buildings: Warehouses, workshops, factories, bridges, culverts.

- Civil works: High-rise buildings, offices, commercial centers.

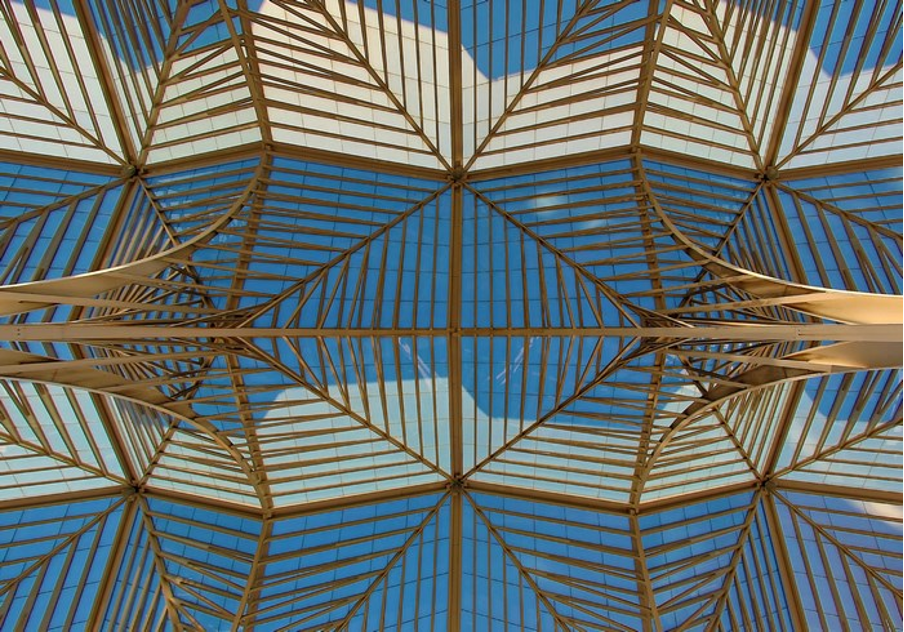

- Public infrastructure: Stadiums, exhibition museums.

- Transport infrastructure: Roads, bridges, ports, cranes.

- Components and equipment for thermal power, hydropower, petrochemical refining, or mineral extraction projects.

2.2 Deep Applications in Heavy Industry:

In addition to thermal power, hydropower, and mineral extraction, steel structures are widely used in many other fields in industry and construction. Below are some other areas where steel structure is applied:

2.2.1 Oil and Gas Industry:

Steel structures are used in building infrastructure systems at ports, oil refineries, gas plants, oil and gas pipeline systems, storage tank systems, and crane structures.

DaiDung Group is a pioneer in the mechanical fabrication of steel structures for heavy industry and energy sectors.

2.2.2 Automotive and Engine Industry:

Steel structures are used in the production and assembly of mechanical parts for automobiles and engines. It is used in vehicle frames, suspension systems, engines and gearboxes, fuel tanks, and other mechanical parts.

2.2.3 Aerospace Industry:

Steel structures are used in the construction of airports, runway systems, air terminals, space infrastructure, and industrial buildings related to the aerospace industry.

2.2.4 Water Treatment and Environmental Industry:

Steel structures are used in building water treatment plants, waste treatment plants, water pipeline systems, and waste containment systems. It is also used in environmental protection structures and fire-resistant structures.

2.2.5 Food and Processing Industry:

Steel structures are used in building food processing plants, breweries, sugar factories, fish processing plants, and other industrial food facilities. It is used in support structures, storage tank systems, and piping systems.

3. Characteristics of DDC Group’s Industrial Steel Structures

3.1 Meeting Load-bearing Requirements:

DDC Group’s industrial steel structures are fabricated to meet criteria for outstanding mechanical properties, high load-bearing capacity, good resistance to deformation, and ease of fabrication and assembly.

3.2 Design Based on Technical Analysis:

Before construction, each DDC Group steel structure is detailed in drawings and undergoes technical analysis during the estimation process. The purpose is to calculate and determine requirements for load, load-bearing capacity, and safety. This structural steel design is always based on current technical standards and regulations.

3.3 Diverse Shapes and Sizes:

DDC Group’s industrial steel structures come in diverse shapes and sizes depending on the type and requirements of each project. Today, all projects highly value aesthetics. Therefore, the design and surface coating of DDC Group’s steel structures become value-adding focal points. In the DDC Group Production Block, the selection process for incoming engineers and skilled welders is rigorous, meeting requirements for both standardized and skillfully crafted fabrication.

DaiDung Group is the general contractor for the Hoa Phat Steel Complex project in Quang Ngai.

3.4 Standardized Steel Structure Production Process:

DDC Group’s steel structures in every project are produced to requirement and meet high-quality standards according to current international certifications. The steel structure production and quality inspection processes are careful, ensuring the accuracy and reliability of the steel components.

3.5 Assembly and Connection Stage:

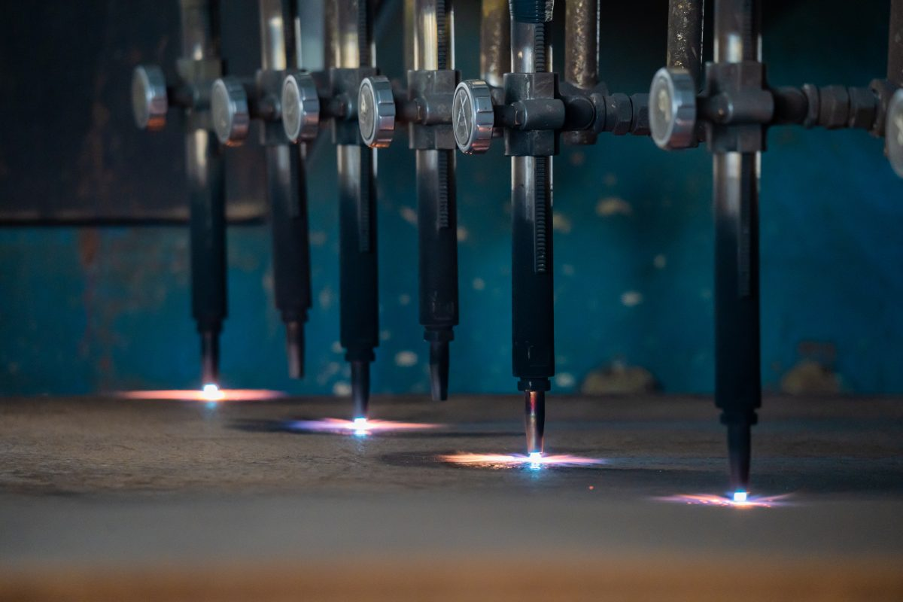

Steel components in industrial structures are often assembled and connected using professional methods such as:

- Welded connections

- Bolted (screw) connections

- Bolt and anchor bolt tightening

- Pin connections. This helps create a solid and safe structure.

3.6 Advanced Technology:

Today’s industrial what steel structures are often supported by advanced technology such as 3D design software, simulation, and technical analysis. This technology helps improve accuracy, efficiency, and project management.

DDC Group’s steel structures, evolving with the times, have made a distinct mark, becoming a leading sustainable development material for the future.

In general, steel structure is widely applied across many different industrial and construction fields. It is considered a component, structure, and framework that provides sustainability, strength, and flexibility, meeting the strict requirements of various industries. And DaiDung Group is the pioneering mechanical fabrication unit, providing leading solutions, design, processing, and erection of steel structures in Vietnam and reaching the international level.